Cemented carbide is a composite material composed of a hard phase and a bonding phase. It is widely used in cutting tools, grinding tools, and mining tools because of its excellent properties, such as high hardness, high strength, high wear resistance, and high thermal stability, geological exploration tools, wear-resistant parts, and other fields. However, the performance of cemented carbide is closely related to its internal structure and organizational state. Therefore, it is crucial to accurately analyze and measure the structural structure and properties of cemented carbide.

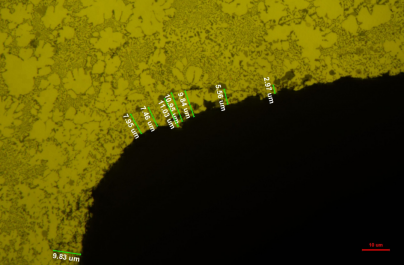

Carbide grain size is one of the important parameters in the structure of cemented carbide. The size of the crystallinity directly affects the hardness, wear resistance, toughness and other properties of cemented carbide. Therefore, the determination of carbide star particle size is one of the important means for quality control and performance optimization of cemented carbide. There are many methods for measuring the maximum particle size of carbides, such as the metallographic method, X-ray transmission method, electron microscope method, etc. Among them, the metallographic method is widely used because of its advantages, such as easy handling and intuitive results. In the metallographic method, the hard, high-quality alloy sample is ground, polished, and etched to make the internal structure clearly visible. Then, the size and distribution of carbide grains are observed through a microscope to obtain information on the carbide grain size.

The degree of pore removal, a key indicator of cemented carbide performance, refers to the volume percentage of pore glands in the material. This parameter directly impacts properties such as density, hardness, and wear resistance. Uncombined carbon, another important indicator, refers to free carbon in cemented carbide that has not been combined with alloying elements. Excessive content can lead to a decrease in performance. Therefore, the metallographic determination of porosity and uncombined carbon is a vital means for quality control and performance optimization of cemented carbide.

In metallographic determination, the internal structure of the cemented carbide sample can be clearly visible by grinding, polishing and etching. Then, by observing the surface or surface of the cemented carbide through a microscope, the distribution and size of the pores can be visually seen, thereby obtaining information on the degree of pore removal. At the same time, through chemical analysis or energy spectrum analysis of cemented carbide samples, the content of uncombined carbon can be measured to gain a comprehensive understanding of the distribution of uncombined carbon in cemented carbide and its impact on performance.

The structure and properties of cemented carbide, intricately linked to the particle size, porosity, and uncombined carbon content of the internal carbide, can be accurately measured and analyzed through metallography. This provides robust support for quality control and performance optimization of cemented carbide. As science and technology advance and new materials emerge, the research on cemented carbide’s structure and properties will continue to deepen and improve, injecting new energy into its application and development.

Supplier

My Carbides is a large enterprise focusing on the research, development, production and sales of copper products. With multiple production bases and R&D centers, its copper products sell well in domestic and foreign markets and are well received by customers.

Complete variety, excellent quality, innovative research and development. Customized services and professional consultation are available. If you need carbides products, please feel free to contact us.